Precision is the backbone of modern manufacturing, especially when working with delicate materials and intricate designs. However, traditional wire processing methods often introduce unwanted heat, stress, and imperfections, making it difficult to achieve the highest quality results. That’s where femtosecond laser technology comes in, offering a game-changing approach that delivers incredible accuracy and control.

At Laser Wire Solutions, we’re leading this precision revolution, using femtosecond lasers to push the boundaries of what’s possible in wire processing. But what exactly makes femtosecond laser processing so revolutionary? Let’s break it down.

Unveiling the Power of Femtosecond Lasers

The term “femtosecond” refers to an astonishingly brief period—one quadrillionth of a second. To put it into perspective, a femtosecond is to a second what a second is to 31.7 million years. This incredibly short pulse duration is the secret behind the laser’s unique capabilities.

Unlike conventional lasers that deliver energy over longer durations, femtosecond lasers emit ultra-short bursts of energy, enabling precise material interactions without excessive heat buildup. This results in:

Minimal Heat-Affected Zone (HAZ): The ultra-short interaction time prevents excessive heat transfer, eliminating thermal damage and preserving material integrity.

Cold Ablation Process: The laser’s energy is so concentrated that material vaporizes instantly, minimizing melting, mechanical stress, and unwanted deformations.

High Peak Power: Despite their low average power, femtosecond lasers achieve exceptionally high peak power, making them effective for processing metals, polymers, ceramics, and composite materials.

Revolutionizing Wire Processing with Femtosecond Lasers

When applied to wire processing, these capabilities translate into unparalleled precision and reliability. Whether it’s cutting, stripping, or micro-feature creation, femtosecond lasers provide a new standard of excellence:

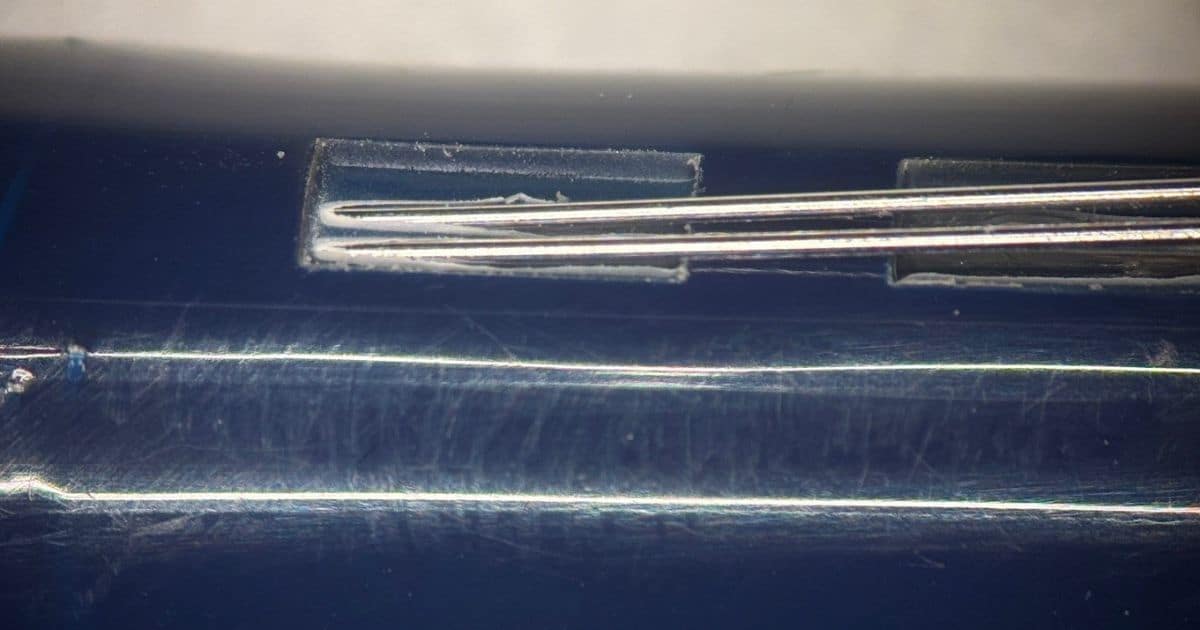

Ultra-Precise Cutting: Achieve clean, burr-free cuts with micron-level accuracy, even on ultra-fine or intricate geometries.

Damage-Free Insulation Stripping: Remove insulation with extreme precision while leaving the underlying conductor untouched—crucial for high-performance medical and aerospace applications.

Advanced Material Ablation: Create micro-slots, tapers, and textured surfaces with a level of detail impossible with conventional methods.

Femtosecond vs. Traditional Laser Processing

Traditional laser processing—whether using nanosecond, picosecond, or continuous wave (CW) lasers—delivers energy over longer periods. This often results in unwanted heat accumulation, which can cause melting, mechanical stress, and reduced precision.

In contrast, femtosecond lasers employ a “cold” ablation process, preventing thermal damage and achieving superior results, particularly for delicate or heat-sensitive materials.

Why Choose Laser Wire Solutions?

At Laser Wire Solutions, we specialize in custom femtosecond laser wire processing solutions designed to meet the most demanding requirements. Our expertise allows us to:

Enhance manufacturing efficiency with cutting-edge laser technology

Deliver superior precision and consistency for high-spec applications

Collaborate closely with clients to tailor solutions for their unique needs

Femtosecond laser wire processing is a paradigm shift in precision manufacturing. With its ability to deliver ultra-short pulses, minimize thermal damage, and enable intricate designs, this technology unlocks new possibilities across medical, aerospace, and high-tech industries.

If you’re ready to experience the next level of precision in wire processing, contact Laser Wire Solutions today to discover how we can help transform your manufacturing capabilities.