On 6th and 7th December 2017 Laser Wire Solutions will be exhibiting for the first time on Booth 220 at the BIOMEDevice San Jose show in California.

Interest from medical device manufacturers in the company’s laser wire stripping technology has grown exponentially since the launch of Odyssey-4 – the company’s newest catheter wire stripper product, introduced at the beginning of 2017. Given that the number one objective of attendees to the show is to discover new products, services and technologies, Laser Wire Solutions believes that this is a prime opportunity to showcase the Odyssey-4’s unique capabilities and generate new levels of interest.

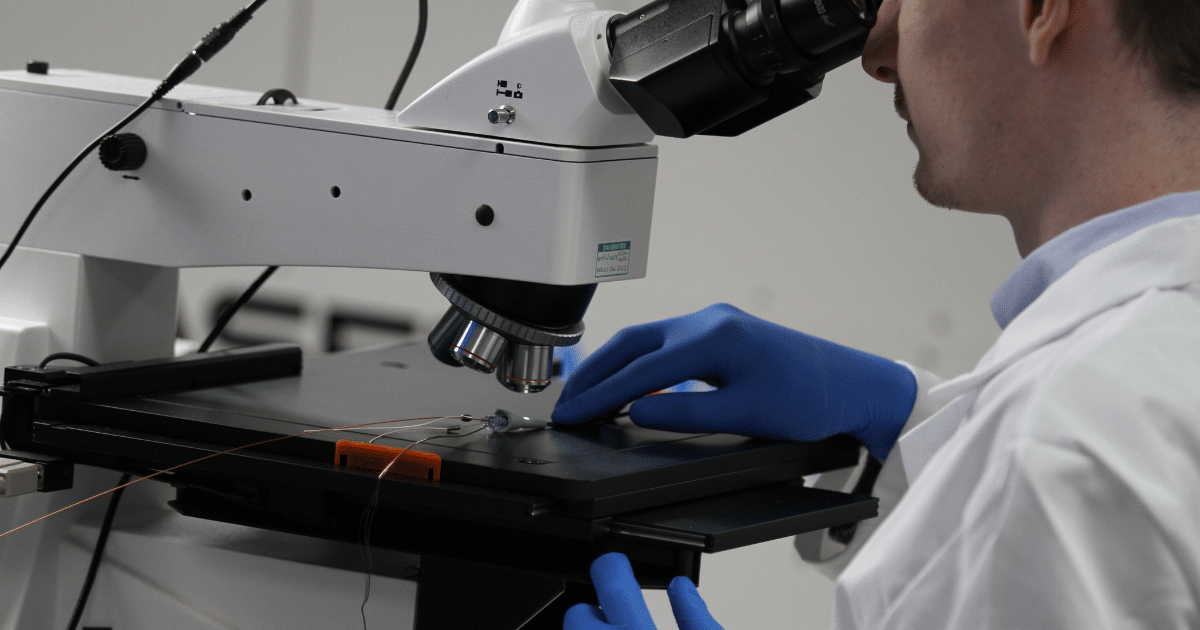

The Odyssey-4 compact UV laser wire stripper was designed to specifically help medical device manufacturers build the next generation of miniaturised, high precision medical devices. The system can be easily retro-fitted into existing lines and can be configured to automatically strip wires inline from spool to spool using a precision wire transport system. The stripping of micron-thin polyimide insulation (such as catheter wires down to 50 AWG – 0.02mm – or less) is clean, fast (typically 1 second) and of a high standard. Strip quality is verifiable with a reliable closed-loop camera vision system monitoring every stage of the process.

With the Odyssey-4, medical device manufacturers now have an affordable, accurate and reliable system that can help them ensure consistency of quality, reduce scrappage rates and improve production efficiencies. Link here for more information on the Odyssey-4.

In addition to the Odyssey-4 stripper, Laser Wire Solutions will also exhibit the well-established and highly regarded Mercury-4 system. Its sleek benchtop design, speed and versatility make it a highly desirable choice for reliable, nick-free processing of a multitude of wires and shielded cables, including single conductors, coax and ribbons. Single wires / cables can be inserted via a port or a fixture plate can handle complex multi-conductors or ultra-thin wires. In-line stripping operation is also an option. Any strip pattern can be accommodated, including angled lines, curves, windows, cross-cuts and slits to perfectly match the customer’s cable layout. The Mercury-4 is distributed through the Schleuniger global sales network. Link here for more information on the Mercury-4.

Laser Wire Solutions has steadily built a reputation as a trusted expert in laser wire stripping. It proves this time and again by developing cost-effective, innovative products that solve customer problems. For customers with small-scale R&D projects, FDA/CE validation or outsourced volume manufacture requirements, Laser Wire Solutions also offers a contract stripping service.

Laser Wire Solutions anticipates this to be an intensive 2-day event with lots of opportunities for the testing of client’s wires and demonstrating proof of capability. The following staff will be on hand to provide demonstrations and deal with your enquiries:

Phil Dodson – Director of Sales & Operations

Dan Nicholls – Technical Engineer

Kevin McClay – Engineer from CAPTEC (Schleuniger representative).

We look forward to welcoming you on Booth 220. For more information on the show, please visit the organiser’s website.