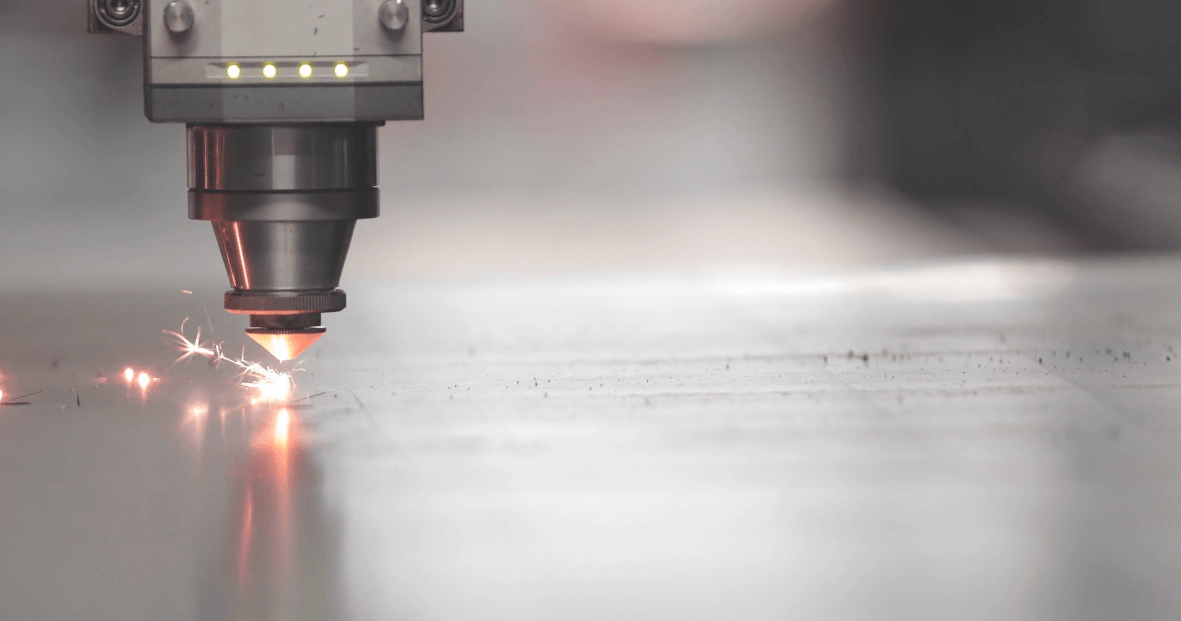

Understanding Femtosecond Laser Wire Processing

Precision is the backbone of modern manufacturing, especially when working with delicate materials and intricate designs. However, traditional wire processing methods often introduce unwanted heat,

Learn with Laser Wire Solutions. From innovative thinking to application expertise, our solutions experts solve your toughest challenges and provide solutions to meet your project needs.

Our technical articles will covers a variety of topics relating to our area of expertise to help solve your challenges.

Precision is the backbone of modern manufacturing, especially when working with delicate materials and intricate designs. However, traditional wire processing methods often introduce unwanted heat,

For engineers designing critical medical devices, the challenge of ensuring biocompatibility in wiring is paramount. While material selection is crucial, the impact of wire processing,

Nitinol stands at the forefront of material science innovation, transforming the landscape of medical device manufacturing and engineering. This sophisticated nickel-titanium alloy has become essential

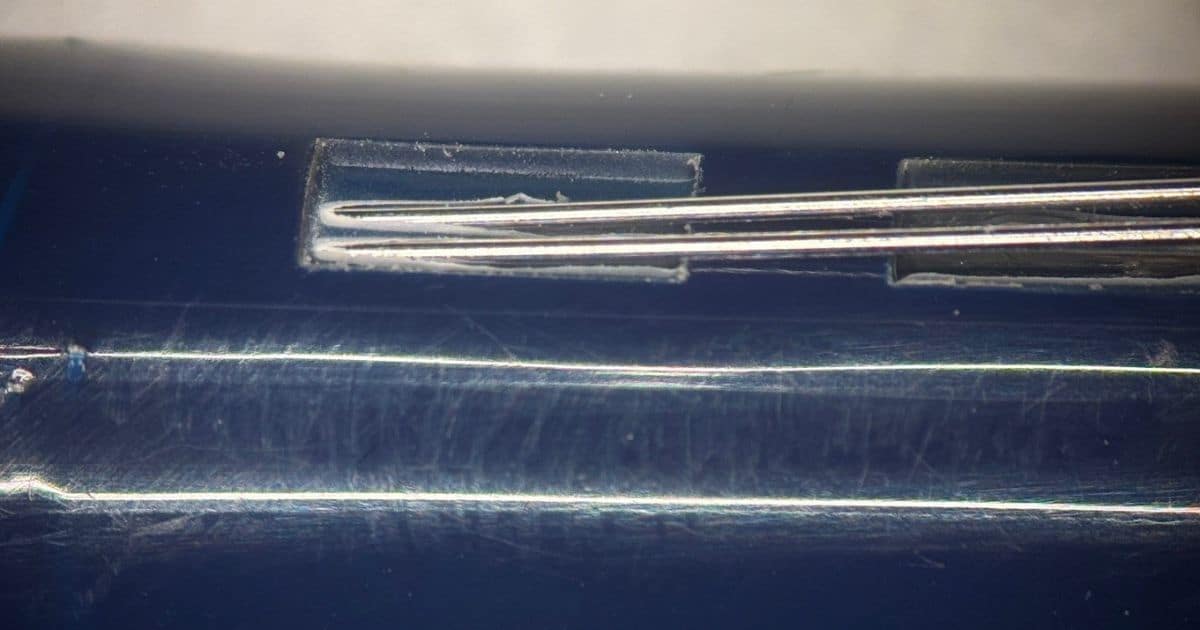

The Critical Role of Precision in Medical Wire Processing Medical device manufacturing demands an unprecedented level of precision, particularly in wire insulation removal. Laser wire

In the intricate world of electronics, particularly in critical industries like medical devices even the slightest electrical noise can have significant consequences. A key factor

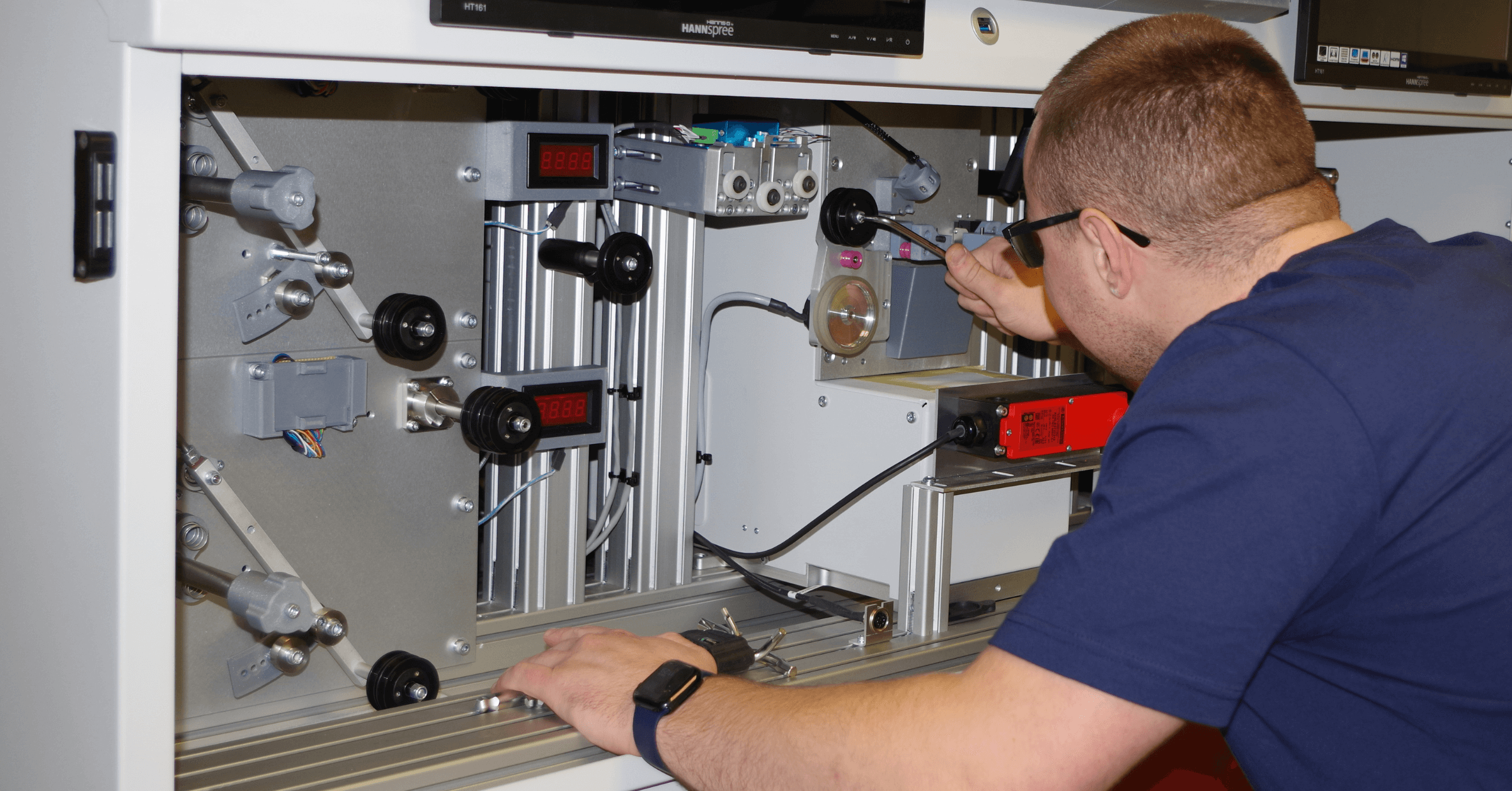

In the ever-evolving landscape of technological advancements, Laser Wire Solutions is thrilled introduce the Odyssey-8. This new machine is the world’s most compact single wire

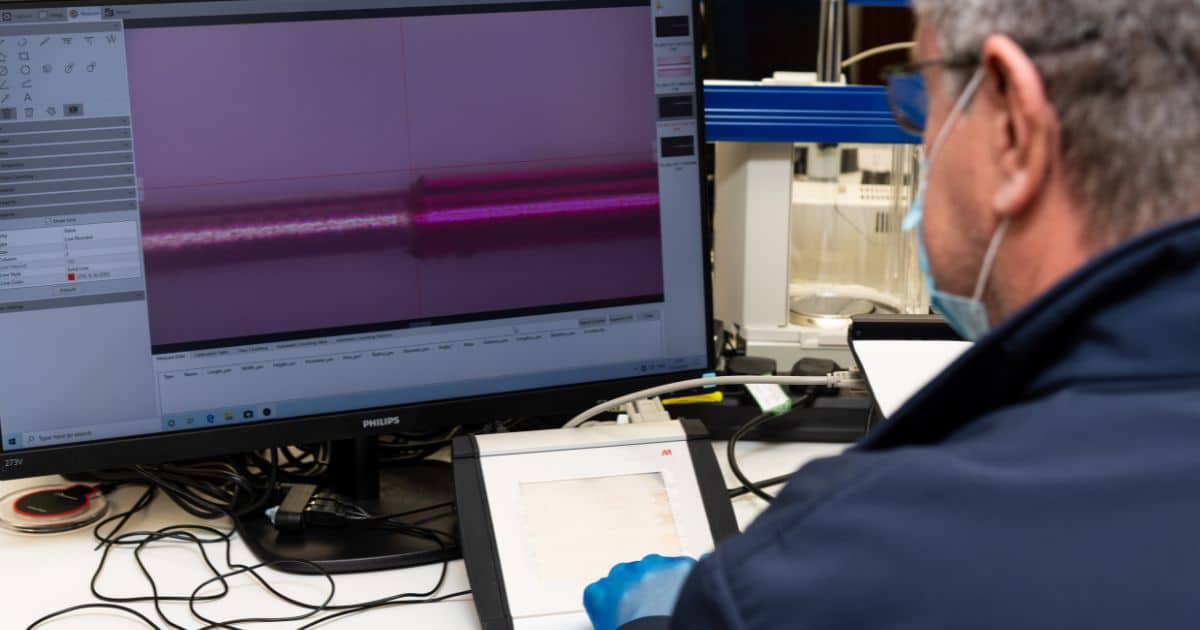

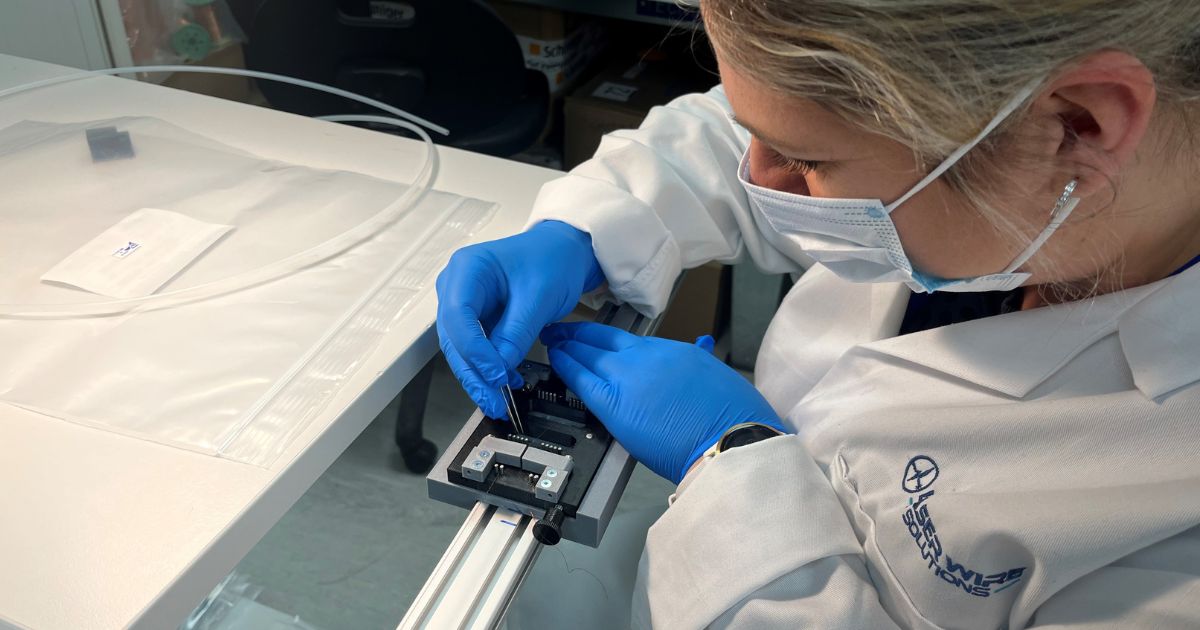

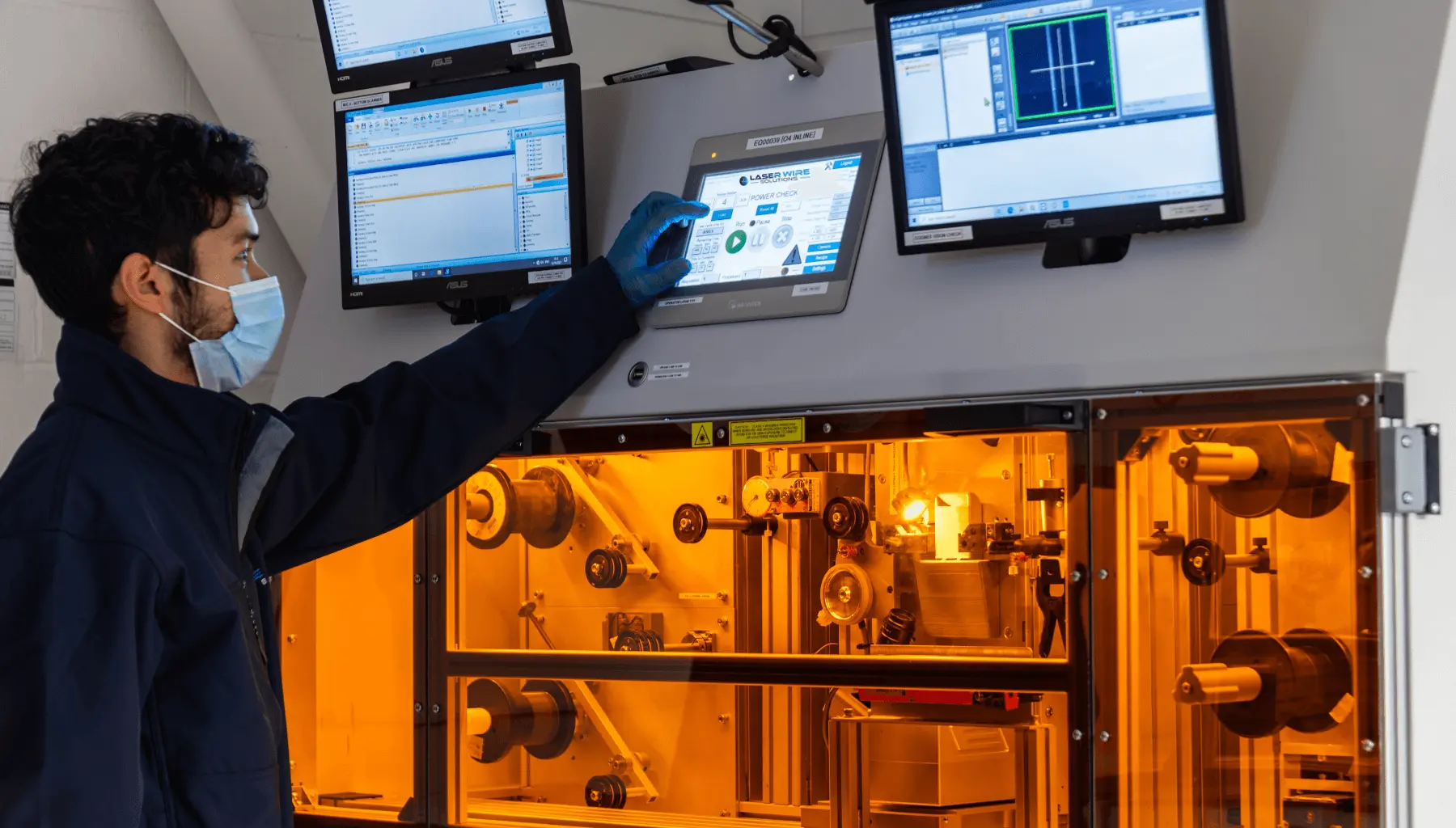

The intricate process of stripping foil wraps from cables, particularly those with delicate underlying insulation, requires a technology that balances precision, efficiency, and the preservation

Insulation stripping is a critical step in many manufacturing processes, but it can also be a source of damage to the underlying wire. This damage

The healthcare industry, while vital, often faces challenges related to environmental sustainability. One such area is the manufacturing of medical devices, particularly catheters. Traditional manufacturing

The Mercury-4 laser wire stripping machine represents a significant advancement in precision wire processing technology. Utilizing a CO2 laser to ablate the outer insulation material

In the fast-paced world of manufacturing, industry standards are the bedrock of quality control and efficiency. One technology that has proven instrumental in meeting these standards is laser

There are some very important factors when deciding on the right Contract Manufacturing partner for your company. Below is a guide on some common mistakes

In an era where businesses are increasingly under scrutiny for their environmental practices, adopting sustainable technologies is not just a moral imperative but also a

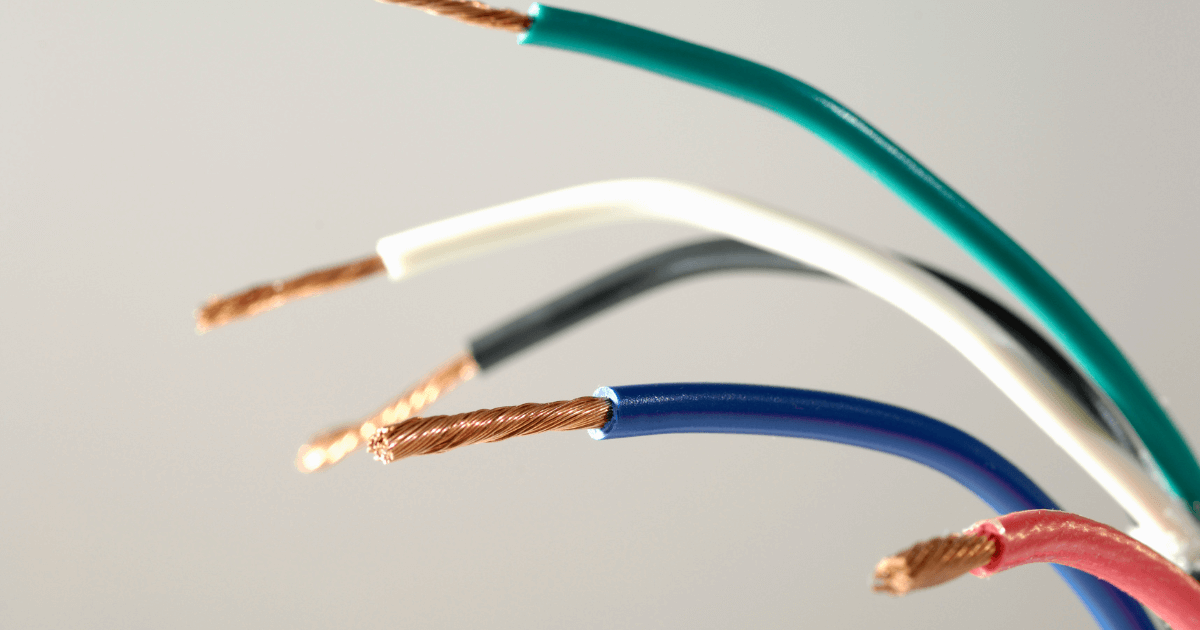

Wires are the unsung heroes of the modern world, connecting us to everything from our smartphones and medical devices to electric vehicles and data cables.

In the world of wire manufacturing, precision and reliability are paramount. Manufacturers dealing with micro fine wires for medical devices, wires with tough insulation, and

In today’s fast-paced world, many people are looking for ways to increase their earning potential. The engineering field is one of the most promising career

ISO 9001 is an international standard for quality management systems. It helps organizations demonstrate that their processes and procedures achieve customer satisfaction and business goals.

It is easy to ignore just how much of our world is made possible by wires. Wires impact everyone’s lives. You will find them as

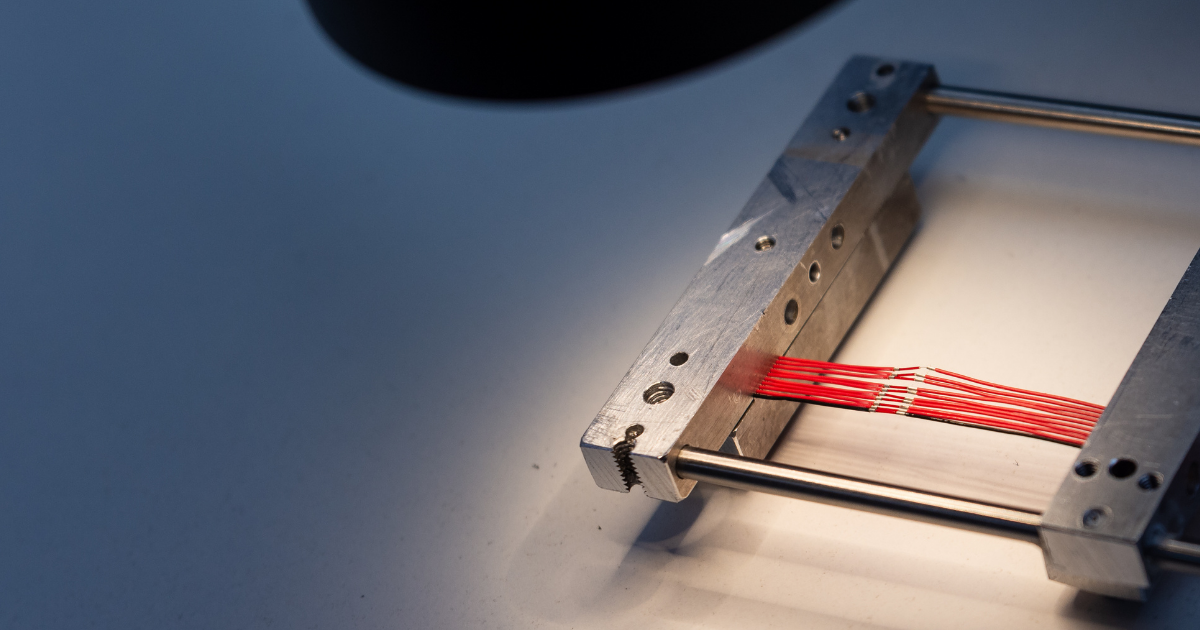

What is Laser Wire Stripping? Laser wire stripping, or laser ablation, is a process that can be used to remove the outer coating of a

Lasers can be an appropriate alternative to chemical and manual wire stripping particularly for high value, very fine wires that are used in medical devices

Only 20 years ago the use of lasers within industry was revolutionary and limited. These days, the rise of medical device applications in electrophysiology, neurovascular,

Laser safety is a primary concern for any organization that plans to operate a laser. A laser can be hazardous to the eyes and skin

To precisely cut a wire part, the laser light needs to be concentrated to the exact point that it is needed. Apart from very large

Laser Type The key to laser wire stripping is finding the laser type that strongly interacts with the layer you want to remove and yet

Laser wire stripping is a process that is used to remove the protective insulation from the end of wires to allow the wire conductor to

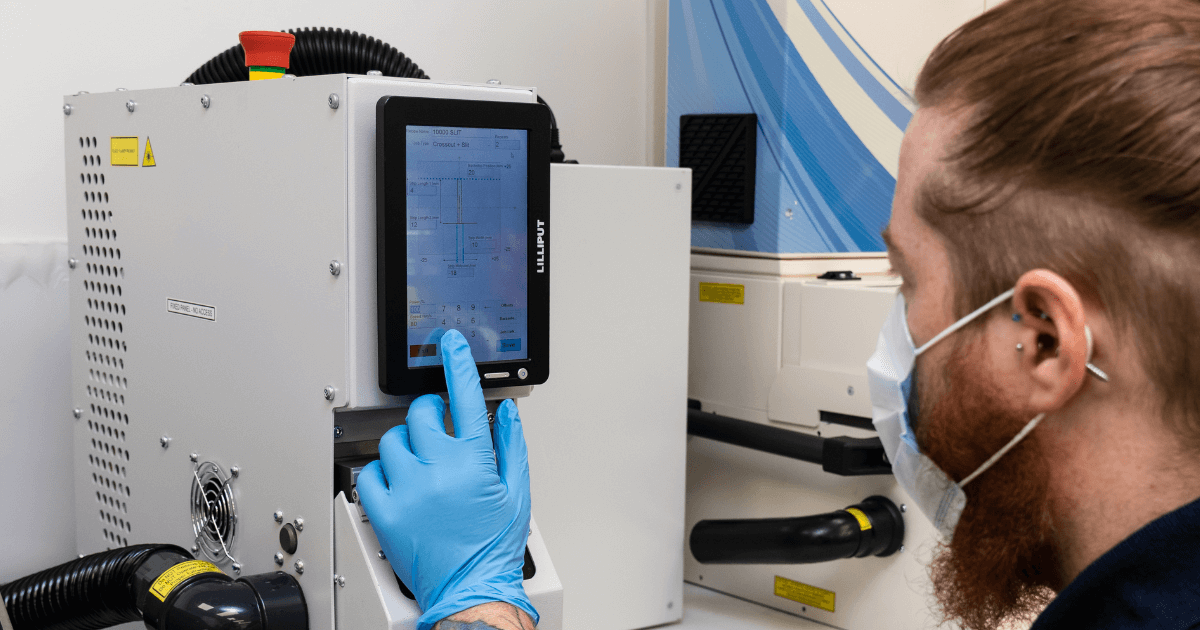

Discover the capabilities of our machines with your application before you buy

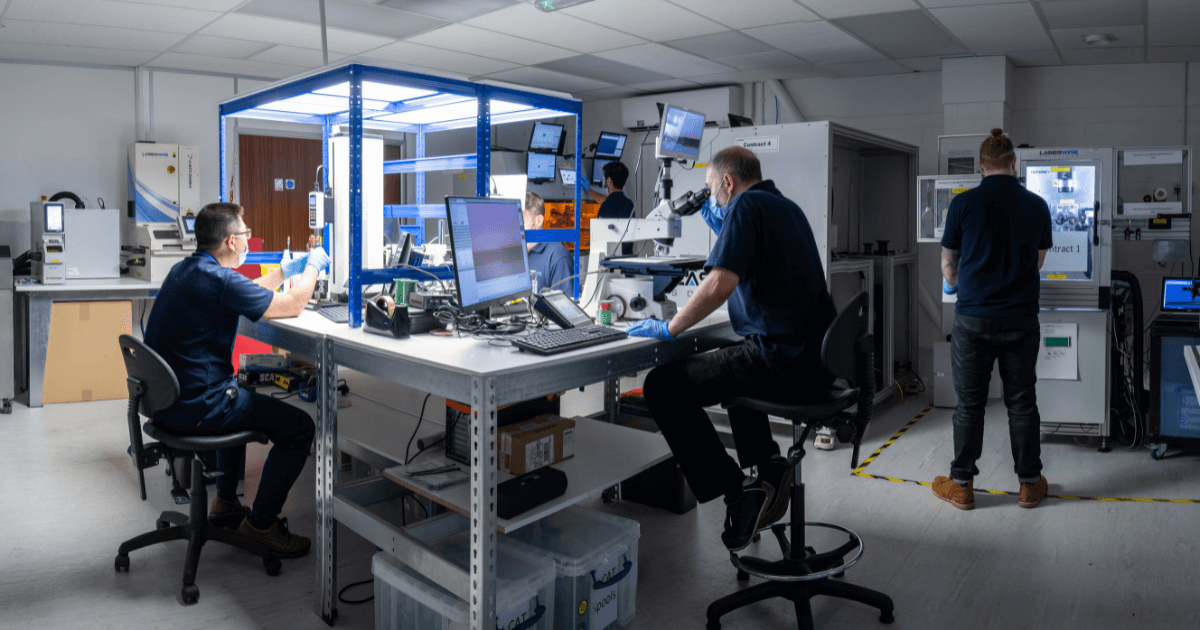

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.