The next generation of data cables present new challenges for achieving the required dimensional tolerances and to allow full automation of the cable manufacture, our laser strippers provide the solution.

Find out more about how our laser wire strippers can be used prior to termination in your production line.

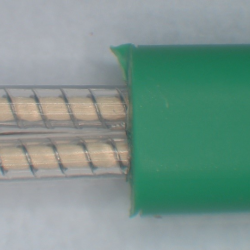

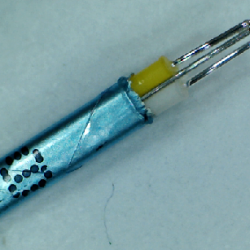

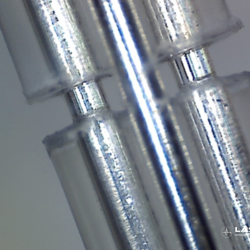

To make a high speed cable with low loss and high performance, it’s necessary to maintain an accurate separation between the foil and stripped dielectric. The dielectric can be difficult to laser cut with high repeatability. The cut line can be jagged and the material can mushroom out due to the heat effect of the laser.

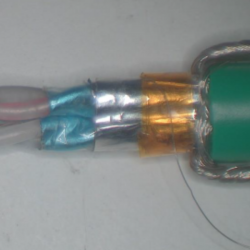

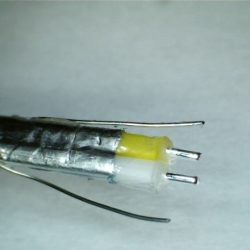

An even greater challenge is the foil cutting. Usually the foil is cut by a blade – but for the smaller next generation cables, the possibility of incomplete stripping leads to tears and tags which ruin the performance and in the worst case produce short circuits.

Laser Wire Solutions are the world leader in novel laser solutions for the stripping of InfiniBand and Gigabit Ethernet cables.

The exact solution depends on whether it will be implemented in a fully automated cable manufacturing line, or a manual assembly operation. It also depends on the cable design regarding placement of the drain wires.

Cables with a single drain can have the foil removed in a single laser process. For those with a dual drain, we have solutions for when the foil requires peeling or laser cutting, depending on the level of quality required.

Discover the capabilities of our machines with your application before you buy

Revolutionizing the medical, data, and automotive industries with the use of lasers and robotics, Laser Wire Solutions is at the cutting edge of laser & robot technology.

© 2025 Laser Wire Solutions. All Rights Reserved.

Laser Wire Solutions registered in England and Wales under the company registration number 07800816. Registered office address: QED Centre, Main Ave, Treforest Industrial Estate, Pontypridd, Rhondda Cynon Taff, Wales, CF37 5YR, United Kingdom.