There are some very important factors when deciding on the right Contract Manufacturing partner for your company. Below is a guide on some common mistakes to avoid, and how to get the most from your successfully chosen Contract Manufacturer (CM).

The most important rule – don’t rush!

Communicate with various manufacturers, it’s an important assessment to see how well samples are processed, how effective the team’s organisation skills are, and to get a general feeling of the preferred method of business. Are they offering solutions? Have they taken multiple calls, given you advice and guidance? Is the potential CM listening to your requirements? Are they offering an adaptive approach? Are the team helpful, approachable, and knowledgeable?

Research.

When looking around for a CM it is essential to research as much as possible on the background of the company. Is the company experienced? Ask for proof of certification, ask for examples of similar applications, visit the location or ask for a remote tour of their facility. There are many ways to go about researching into the correct CM, the choice must be right for your product and your team/end client. Don’t think short-term, build relationships within the CM unit this will provide you with more over-sight on your product as well as more frequent feedback from the CM team.

Compare results and services

Compare as many samples as possible, from local contractors to international ones. Who is offering more of a service? Which CM is offering price negotiation? Don’t be afraid to discuss with your CM some of the offerings that you have seen elsewhere. Ask to have a preview of a contract agreement, are there any extra offerings involved? Compare agreements.

Be honest about difficulties

To get the most out of your CM, be honest with what you don’t understand. If the decision is going to a non-technical person, talk to your CM about this. What supporting documents can the CM offer you for a commercial executive? Talk to your CM about what good service and agreements look like to you. The more information you provide the CM, the more they have at hand to work with when providing an exceptional service. This will allow the CM to re-assure you about any future worries and to suggest plans to put in place to make manufacturing smooth, such as staggered delivery or preferred payment options. This is also a brilliant test to see how the CM would react in a difficult situation, throw as many problematic issues as possible that you can think of and judge their “on the spot” solutions. The more they offer to your situation the better. Listen out to see if they bring up other clients and similar issues, this is a good sign as this tests their experience and on the ground knowledge.

Going local doesn’t always equate to better results

A common myth is that using a local manufacturer will provide you with more control over your product. The fact still remains that you will be unable to drop in on your product line whenever you’d like; due to production being in run, staff being pre-occupied with other production jobs and client privacy. Entering the manufacturing unit would require a written confirmation and there is no guarantee that because you are local that your CM is viewing you as priority, it may turn out that the local CM is actually getting more from an over-seas contract.

Choosing the right Contract Manufacturer (CM) for your company involves careful consideration and strategic decision-making. It’s crucial not to rush the process and to communicate effectively with potential manufacturers to assess their capabilities, responsiveness, and adaptability. Thorough research into the company’s background, experience, and certifications is essential, as is building long-term relationships for better oversight and feedback. Comparing results and services from various CMs, both local and international, can help identify the most beneficial offerings. Open discussions about these offerings and contract agreements can lead to more advantageous terms. Being honest about any difficulties or lack of understanding can enable the CM to provide better service and reassurance, as well as test their problem-solving abilities.

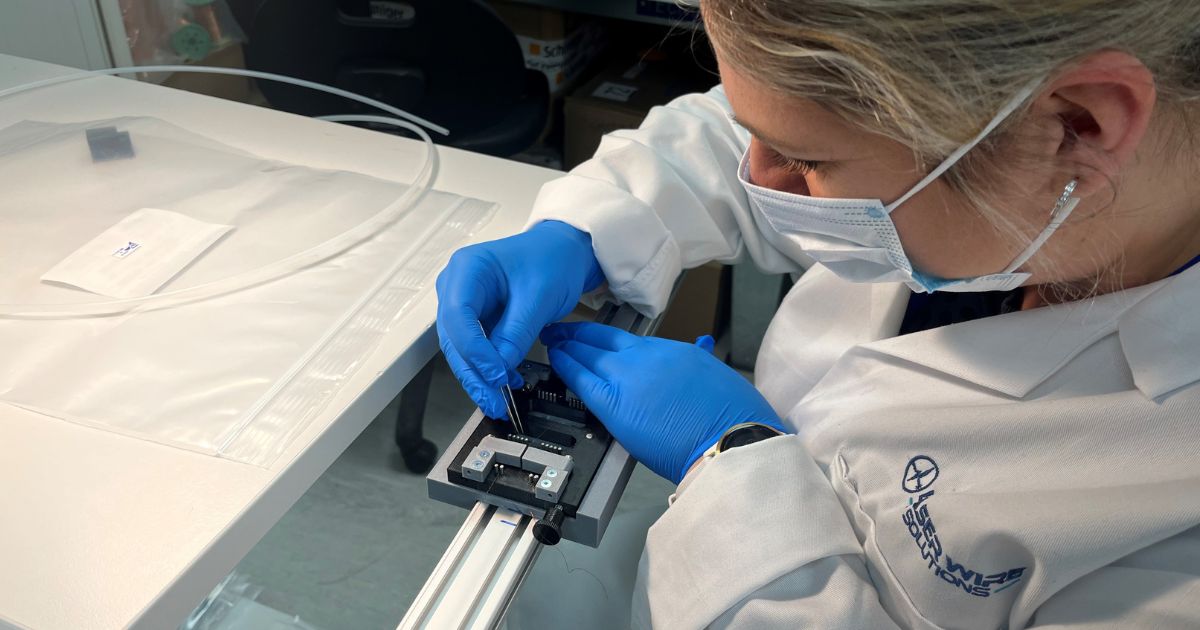

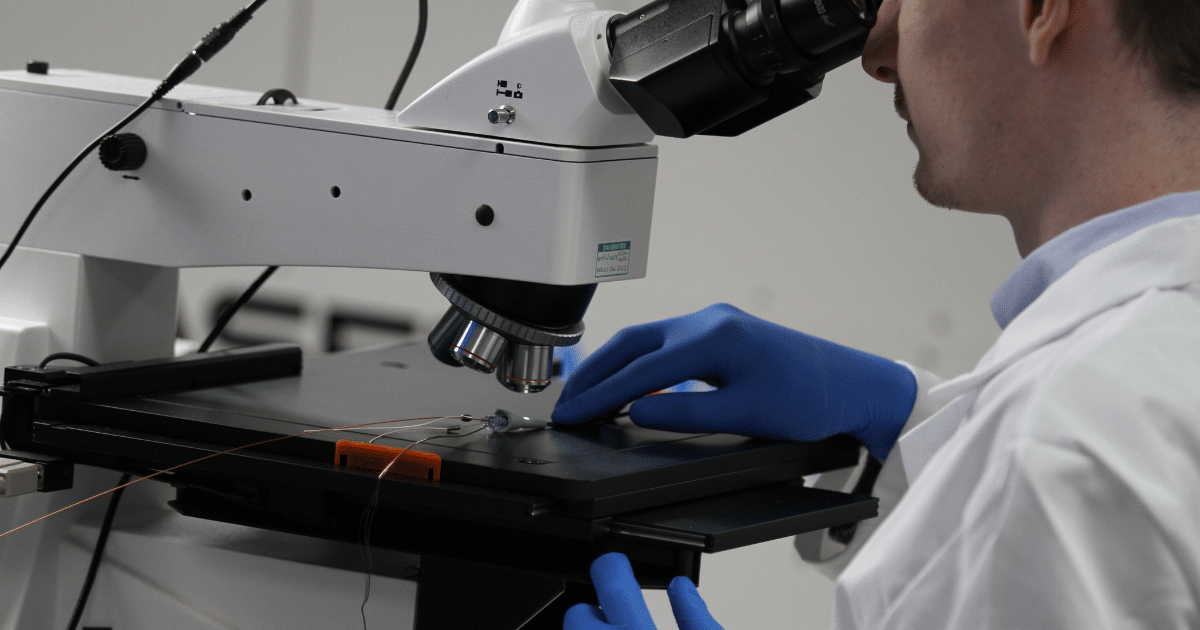

At Laser Wire Solutions, we have extensive experience in our contract manufacturing ablation service. As an ISO 9001:2015 certified service, we’re able to provide the highest quality laser stripped wire available on the market. Find out more about our Contract Ablation Service, here.