Wires are the unsung heroes of the modern world, connecting us to everything from our smartphones and medical devices to electric vehicles and data cables. But before they can perform their crucial role, they need to be effectively stripped for connection. However, not all wires are created equal, and not all wire stripping methods are suitable for every application. In this blog post, we’ll delve into the world of wire stripping and explore three different methods – mechanical wire stripping, chemical wire stripping, and laser wire stripping. By the end, you’ll have a clear understanding of which method is best suited to your specific needs.

What Is Wire Stripping?

Before we dive into the different methods, let’s clarify what wire stripping is. Wire stripping is the process of removing the insulating material from the wire to expose the conductor. This is essential for making electrical connections, ensuring the integrity of the signal, and maintaining electrical conductivity.

Mechanical Wire Stripping

Mechanical wire stripping, as the name suggests, involves physically removing the insulation from the wire using a mechanical tool or device. This method is best suited for thicker wires and cables, such as those found in construction or heavy-duty electrical work. Some key points about mechanical wire stripping:

Pros of Mechanical Wire Stripping

- Ideal for larger wires.

- Low upfront cost.

- Suitable for on-site applications.

Cons of Mechanical Wire Stripping

- Limited precision for small wire sizes.

- May cause damage to delicate wires.

- Labor-intensive for high volumes.

Chemical Wire Stripping

Chemical wire stripping is a process where the insulation is dissolved using a chemical solution. This method is often used for fine and delicate wires found in industries like electronics and telecommunications. Here are some important considerations for chemical wire stripping:

Pros of Chemical Wire Stripping

- Ideal for small, delicate wires.

- High precision.

- Suitable for batch processing and automated systems.

Cons of Chemical Wire Stripping

- Chemical disposal and safety precautions are necessary.

- Initial setup and maintenance can be costly.

- Not ideal for all types of insulation.

- Some damage may occur to the wire when removing the insulation.

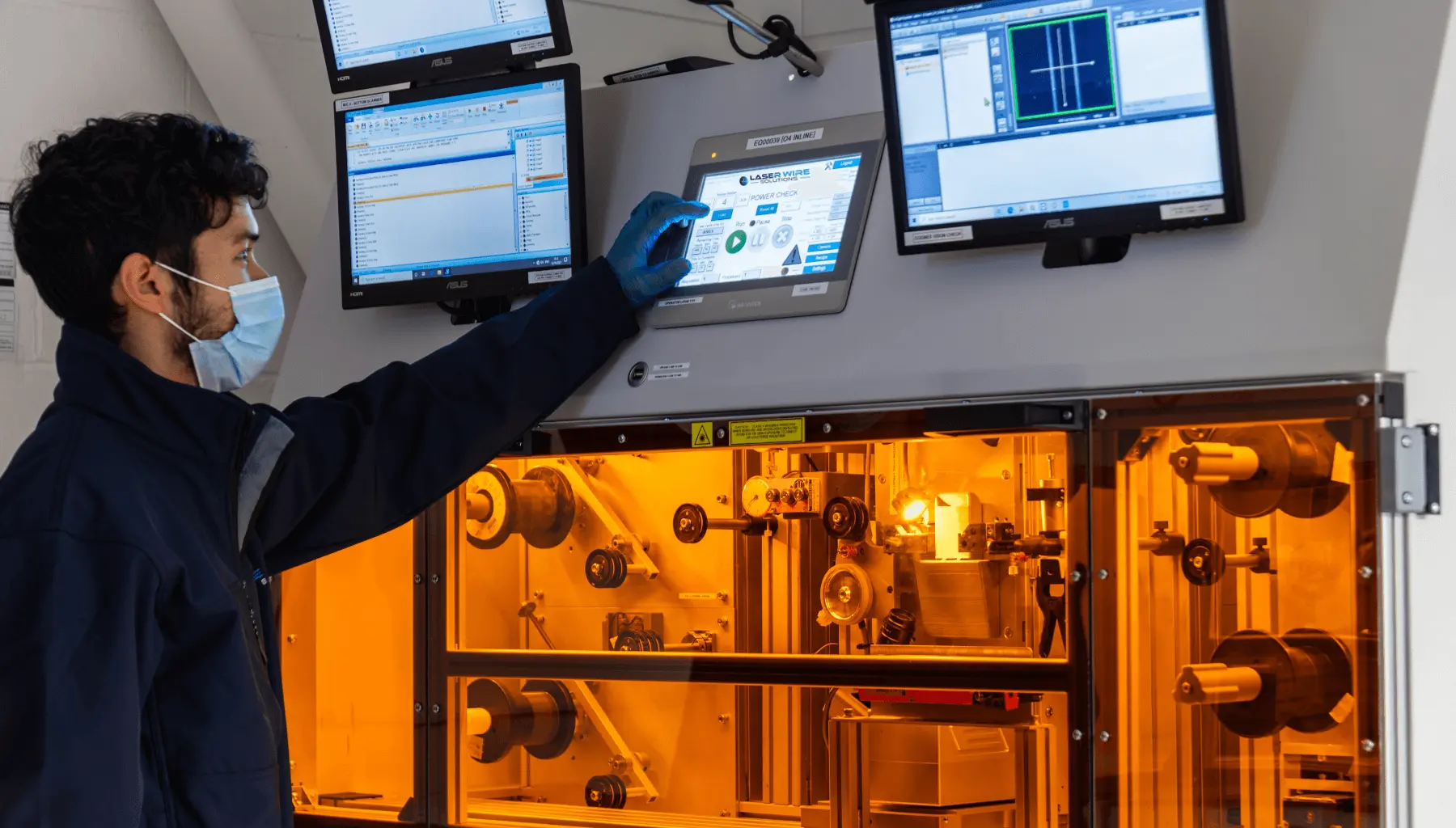

Laser Wire Stripping

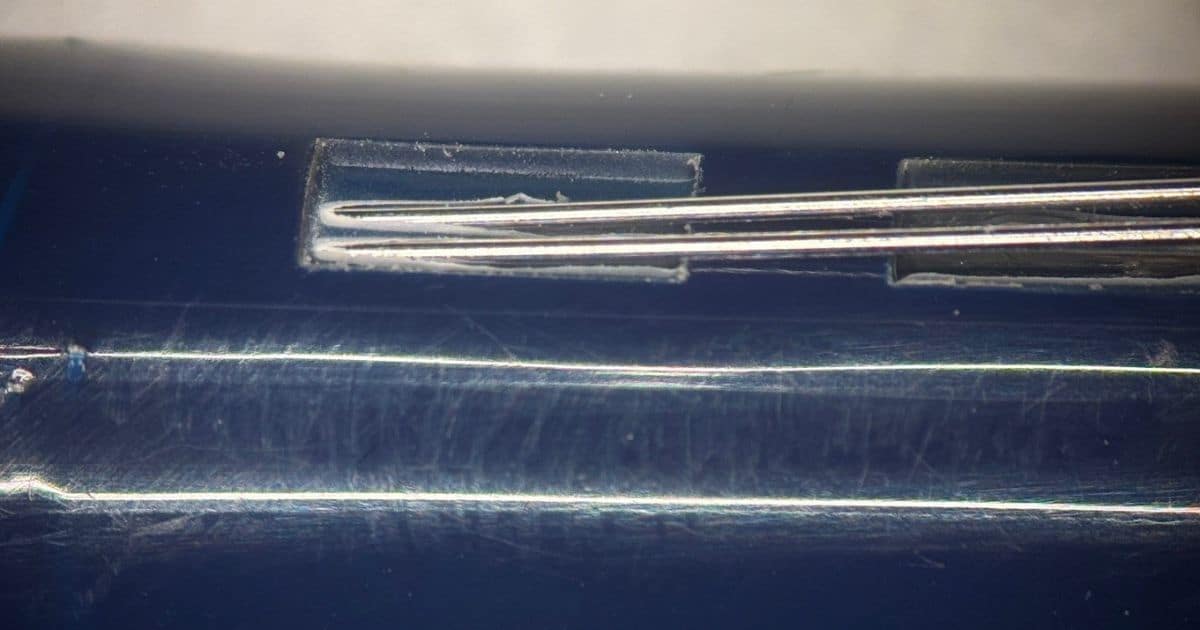

Laser wire stripping is the most advanced and precise method of wire insulation removal. It uses a focused laser beam to precisely remove the insulation without causing any damage to the conductor. This method is versatile and highly efficient, making it suitable for various industries. Some key points to note about laser wire stripping:

Pros of Laser Wire Stripping

- Exceptional precision for wires of all sizes.

- Minimal risk of wire damage.

- Suitable for high volumes and automation.

- Environmentally friendly, as it does not use chemicals.

Cons of Laser Wire Stripping

- Higher initial investment for laser equipment.

Laser wire stripping offers exceptional precision and versatility, making it suitable for various applications. Take a look at our Applications pages to find out where your application fits with laser wire stripping.

In conclusion, the choice of wire stripping method depends on your specific needs and the types of wires you are working with. For small, delicate wires in industries like electronics, chemical or laser wire stripping may be the best option. In contrast, for larger wires and on-site applications, mechanical wire stripping may be more practical. The key is to understand the advantages and limitations of each method to make an informed decision that ensures your wire connections meet the highest standards of quality and reliability.